Project Tracking

Engineers can keep track of the ongoing operations by using live monitoring, which provides real-time updates on various aspects, including the main task of drilling, as well as other details like inventory, on-site equipment, personnel on board, and more.

Real-time Tracking

The insights gained from real-time monitoring enable informed decision-making and facilitate the optimization of drilling performance.

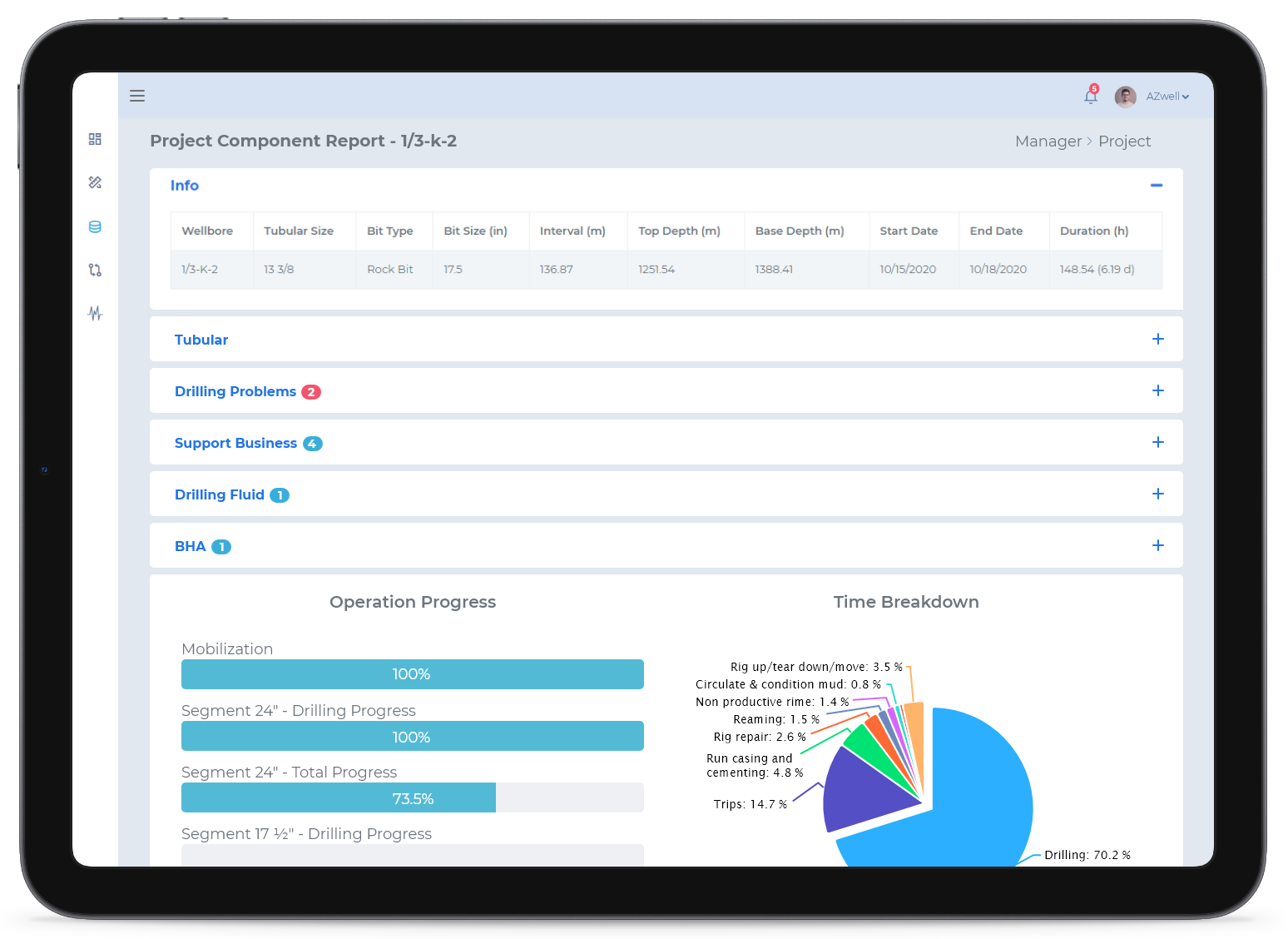

Project Status

Project status, provides progress information based on the well plan. It enables engineers and managers to track the last status of project and aware of completed phases.

NPTs and Problems

Problem reports provide valuable insights and details about the challenges encountered during operations. By reviewing previous records, engineers and managers can identify similar problems and recommend appropriate solutions.

Service Providers Activities

Activity analysis enables managers to identify the share of each service provider and suggest focus areas to service companies for performance optimization. This helps clients and service companies avoid extra costs and optimize operations.

Equipment Performance

Drilling operations involve the use of various types of equipment, each of which can have an impact on performance. Monitoring a series of metrics can help engineers identify opportunities to optimize performance, reduce costs, and shorten drilling operations.

Facility Activities

Analysis of facility activities provides insights into facility usage during operations. This helps engineers optimize operation costs by employing an appropriate number of facilities.

Inventory Analysis

Analysing additive usage is a way to improve operational performance and logistics planning. Insights gained from inventory data enable engineers to understand additive performance and maximize efficiency.

Completion Intervals

Provides the completion interval records and related activities in a wellbore.

Downhole Equipment

Well installed equipment profile and related activities enable engineers to track the status of well completion.

Integrated Daily Report

The reporting platform is accessible to engineers from the client, operators, and service companies, enabling them to complete daily reports within an integrated system. Depending on their access rules, each user can access different parts of the system.

Activities

Engineers and managers have access to real-time activity reports and can identify potential challenges. By reviewing activity details, users can monitor project progress and provide feedback to the operations team.

Service Report

Representatives from service companies can fill out a report form on the DrillQ panel, and office team members have instant access to the service reports. This enables engineers to track project progress and provide feedback on upcoming activities to operation team.

Equipment

Operation supervisor can report the status of equipment, and the office team can track its impact on operational performance. This report enables engineers and managers to evaluate equipment performance and associated costs.

Material

A drilling fluid engineer can report the amounts of additive materials consumed, as well as mud properties. Analysing this report enables engineers to identify material performance and optimize operation costs by using high-performance materials.

Logistic Report

The logistic activities can be reported by the operation supervisor and tracked and analysed by the office team. The report includes details such as cargo, carrier, origin, and destination. Analysing the logistic reports enables companies to optimize activities, avoid extra costs, and eliminate unnecessary activities.

Crew Activities

Operation crew is essential for the efficient allocation of accommodations, as it allows the office team to track the crew's schedule. By access to this information, the team can also anticipate and prevent possible challenges, such as delays due to unavailability of lodging, and ensure that the operation runs smoothly.